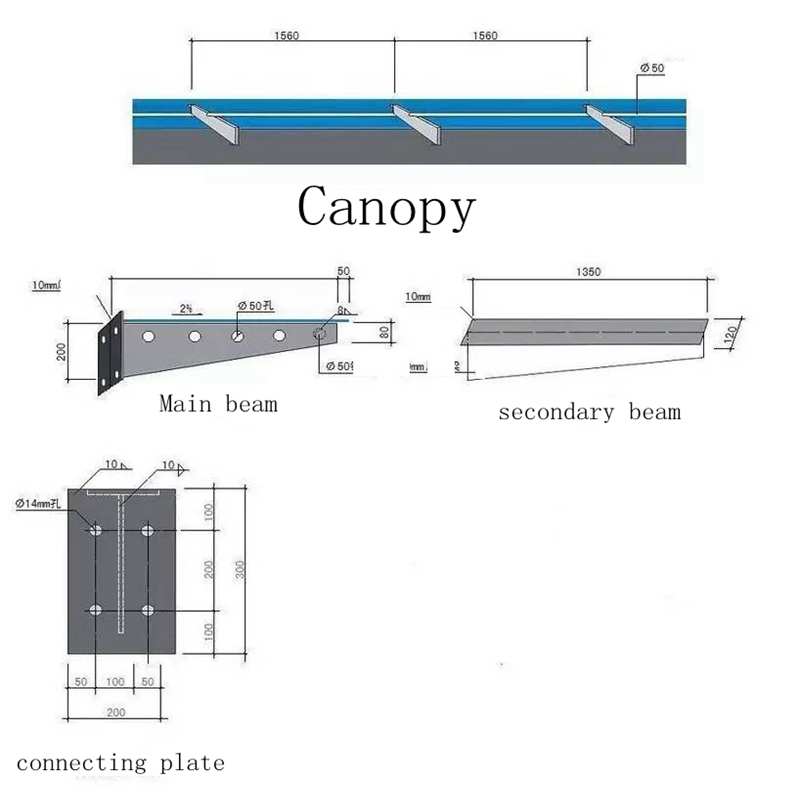

The Structural Steel Frame canopy is built between two buildings as aisle canopy, or is placed above the entrance or top of the building to prevent from rain and wind. A building assembly in which fall objects fall and protect. It is Applicable to industrial plants, schools, residential areas, office buildings etc. The main structure is steel frame, the top is made of steel sheet, sandwich panel or daylight tiles

The canopy is one important steel parts for steel frame buildings, Different canopy for steel frame buildings has different installaiton method and connecting way. The following construction process of canopy is just for reference.

1, Preparation and cutting

According to drawing of steel frame buildings, the welding shrinkage and the machining allowance should be reserved when stakeout and numbering, and the sample should be made according to the stakeout. Before the material is cut, the steel must be corrected. The deviation value after correction should not exceed the allowable deviation.The hot-worked profiled steel is first hot-processed, and the hole is drilled after cooling. Other accessory including embedded parts shall be sprayed with anti-corrosion paint.

2 measuring

According to the civil engineering reference line, the center line of the embedded parts is measured, and then determine the adjustment scheme for the separation of the embedded parts. The ink mark on the outer edge of the slab is used to define the top line of the embedded part of steel frame buildings.

3 embedded parts installation and treatment

Position the embedded parts The embedded parts are required to be positioned accurately and buried firmly. The elevation deviation is not more than 9mm, and the left and right displacement is not more than 20mm.

4, Suspension arm mounting welding

The suspension arm is mounted by welding. To check the welding joints ,After the one side of the suspension arm is accurate, install one of the suspension arms on the other side, place it in place after accurate positioning. Then, the highest and bottommost elevation lines of the suspension arm are pulled out based on the two suspension arms, The remaining suspension arms are welded one by one. When the steel is to be connected, the head is welded and straightened. When the steel joint is used, in order to make the joint steel and the steel plate embedded, the corner should be removed according to the design requirements. The butt welds shall be welded with arc-leading plates at both ends of the weld. The material and wave-port type are the same as the weldments, and the gas cuts are removed and smoothed after welding.

5 calibration test

After installing the suspension arm, The installation quality of the suspension arm mainly checks the non-perpendicularity of the vertical surface of the suspension arm; the side of the vertical surface of the suspension arm is drooped; the slope of the suspension arm. Ensure that the suspension arm meets the design stress state and overall stability requirements.

6 connection force cable

Position the drawbar based on the line and elevation line, install the embedded parts and weld the railings.

7 stainless steel glass claw mounting welding

According to the design size, clamped by the clamp, and the spot welding is performed. After the assembly is completed, the glass claw base is welded.

8, Anti-rust paint treatment

The slag and spatter should be removed, and the surface of the stainless steel parts should be sprayed with white paint. Paint on the inside of the limb steel shall not be leaked.

9 laminated glass processing and installation

Install stainless steel glass claws, adjust the glass temporarily, adjust the standard horizontal, vertical, and flat. The deviation must not exceed the specified deviation.

10 Glue

Thoroughly clean the gap between the glass, there should be no water, oil stains, paint, rust, cement mortar, dust, etc. After the glue is applied, the surface of the glue is smoothed and the excess glue is removed. After the injection is completed, tear off the protective paper and wipe the glass with a solvent if necessary. Do not get dust and scratches before the glue is completely cured.

11 Glass cleaning

After confirming every parts of structural steel frame are ok , clean the glass dust as a whole, and if necessary, wipe the glass with solvent and wait for acceptance.

-

BR PREFAB went to Japan to exchange construction technology

BR PREFAB went to Japan to exchange construction technologyAs member of Chinese Steel Structure Association, BR PREFAB was invited to Janpan to exchange construction technology

BR PREFAB gained a deeper understanding of Japan's advanced technology , particularly in seismic performance, environmentally friendly materials, and intelligent construction. Japanese management system and construction mode also ...Do you like ?0

Read more -

BR PREFAB attend Worldbex in Philippines

BR PREFAB attend Worldbex in PhilippinesWORLDBEX stands for the Philippine's building and construction exposition. it is a pillar of the country’s construction and design industry for its premiere and world-class trade presentations. Gathering the finest local and international companies that cater to a wide variety of construction and design needs, WORLDBEX is supported and acknowledged by distinguished sectors and or...

Do you like ?0

Read more -

BR PREFAB attend The Big5 construct exhibition

BR PREFAB attend The Big5 construct exhibitionLaunched in 2010 with a mission to fully equip Saudi Arabia’s construction sector amidst its huge development plans, The Big 5 Saudi is the Kingdom's leading construction event. The Big 5 Saudi continues to serve as a true testament to the country’s growing attractiveness in the global construction arena, bringing together industry players in support of the Kingdom’s ambit...

Do you like ?0

Read more -

Prefabricated Houses Matchmaking Meeting Of Overseas Projects-BR PREFAB

Prefabricated Houses Matchmaking Meeting Of Overseas Projects-BR PREFABPrefabricated Houses are in big demand of developed countres. From May 15th to 17th, 2019, the 11th China (Guangzhou) International Integrated Housing Industry Expo was held at the Poly World Trade Expo Expo. BR PREFAB was invited as a leader in China's green assembly building. BR PREF...

Do you like ?0

Read more -

Prefab Houses Factory Completed The Audit of ISO9001

Prefab Houses Factory Completed The Audit of ISO9001The prefab houses factory of our group successfully held the audit meeting of ISO9001 quality management system in our manufactured homes factory On June 18, 2019, . The meeting was hosted by Mr. Chen, a consultant from Guangzhou Consulting co.,. All the senior...

Do you like ?0

Read more -

Prefab Steel Structure Factory attended 124th Canton fair

Prefab Steel Structure Factory attended 124th Canton fairPrefab Steel Structure Factory BR PREFAB focus on labor camp, container house, steel structure, light steel villa, portable toilet and security room for more than 10 years. The booth stand are located in the brand area, That is a place to meet...

Do you like ?0

Read more